(Source: Innoform Coaching GbR)

The 8th European ‘Stand-up Pouch Conference’ on the 6th and 7th of November in Vienna provided an impressive demonstration of how sustainable, practical, and cost-effective stand-up pouches are as a packaging format. With excellent barrier properties, reduced packaging materials, and smart design, they succeed in creating new, consumer-friendly packaging solutions.

Dieter Finna

The growth of stand-up pouches remains strong. The speakers in the specialist presentations demonstrated very impressively why this is the case and how the market is continuing to develop from different perspectives. As part of the Innoform event series, Karsten Schröder organized and moderated the conference, which, now in its eighth year, brought together experts from industry, research, and brand owner companies.

Sealed Air’s “BUILDR” platform supports users in early packaging development stage. (Source: Sealed Air Corporation)

In his presentation “Supercharge Your Packaging” Dani Tulchinski from Sealed Air Corporation introduced their BUILDR platform. BUILDR helps brands to successfully launch their pack products to market and minimize the risk in their packaging investment, with data-driven innovation and sustainable, flexible packaging pouch and rollstock solutions.

With a customer-focused and service-driven approach, BUILDR services supports clients through material selection, format and size optimization, design, messaging, and product pricing elasticity. Furthermore, brand owners can select rapid prototyping (digital and/or physical), thus gathering customer feedback within hours on their packaging tailored to industry-specific needs.

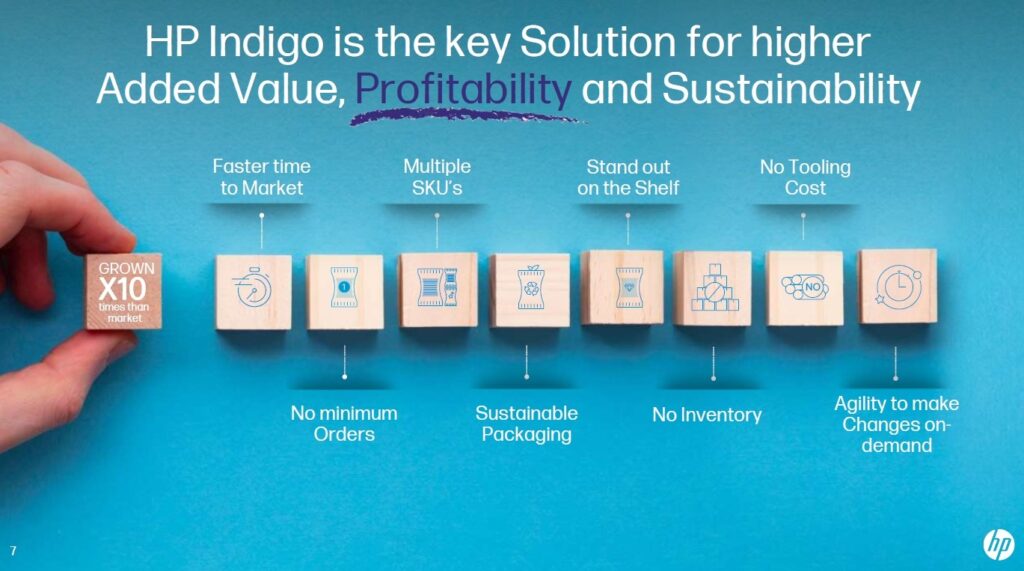

Advantages of Digital Printing for Stand-Up Pouches (Source: HP Indigo)

In his presentation, “Sustainability as a Business Enabler,” Josep Isart from HP Indigo outlined the reasons why digital printing offers advantages in the rapidly growing market for stand-up pouches. Building on the well-known benefits of digital printing, such as short-run production with quick turnaround times, a major trend driving the shift from rigid to flexible packaging is sustainability through refill-ability. Brands benefit from switching to flexible packaging with lower production costs, improved logistics, often larger decoration areas, greater shelf visibility, and overall enhanced sustainability.

The standardized product range of Labelsiten made from PP laminated film. (Source: Labelisten)

Nina Beck from Labelisten presented, “Small Amounts – Huge Variety,” in which she explained why large clients increasingly require smaller order quantities. As the lifecycle, batch size, and lead time of products continue to shorten, the demand for personalization, limited editions, and design variety is rising – trends that are making production processes more complex. Labelisten addresses this challenge through material standardization and the use of digital printing, both of which enable a high level of design variety for stand-up pouches. Combined with a simplified ordering process, this approach enables just-in-time deliveries, sometimes within just a few hours.

Presenting “High-Performance Mono-Material Pouches with Ultrasonic Sealing,” Stefano Di Maiolo from Wipf AG explained the advantages of ultrasonic sealing technology, which significantly expands the applications for recyclable mono-PP and mono-PE pouches. Since the method applies energy precisely and selectively as heat, it enables reliable, damage-free sealing of heat-sensitive monomaterials. This results in a wide range of packaging solutions, from sterilizable and pasteurizable mono-PP pouches with high oxygen barriers to mono-PE and mono-PP stand-up pouches with functional features like spouts. He also spoke of an investment in a triplex laminating system using solvent-free adhesives, the first of its kind. This system leads to a significant reduction in greenhouse gas emissions at Wipf AG.

Recyclable coffee packaging made from PP mono-material – without adhesive and lamination. (Source: Polifilm Extrusion GmbH)

In her presentation, “Stand-up Pouches – Sustainability Well Positioned with PE & PP Monofilms,” Susanne Zobel-Reusch from Polifilm Extrusion GmbH introduced innovative monomaterial solutions. For the printable outer layer, MDO-PE films offer a full replacement for PET, with an optional EVOH oxygen barrier, available as an ultra-thin 18 µm film. Additionally, there are PP-based, printable, and early sealing films that are sterilizable and exhibit low shrinkage.

As an all-in-one solution for stand-up pouches, Polifilm offers a PP monomaterial film with an EVOH barrier and a low sealing temperature, eliminating the need for lamination. This solution has already proven effective for coffee packaging and can be flexibly adapted to meet specific requirements.

The joint presentation by Lutz Neugebauer (Südpack Verpackungen) and Thomas Fuest (SN Maschinenbau) discussed a “Paradigm shift for spouted pouch fillers” through the option of in-house production. They introduced a turnkey three-component system that includes a pouch machine, film, and spout (Menshen), offering production reliability and time savings. Insourcing optimizes the value chain and shortens time-to-market. The new recyclable laminated mono-PP pouches reduce packaging weight by 7.2% compared to PET/Alu/PET/PE laminates and lower CO₂e emissions by 58%. The monomaterial pouches have a recyclability rating of 96% according to cyclos-HTP. The component system also offers potential cost savings in the double-digit percentage range compared to pre-made spouted pouches.

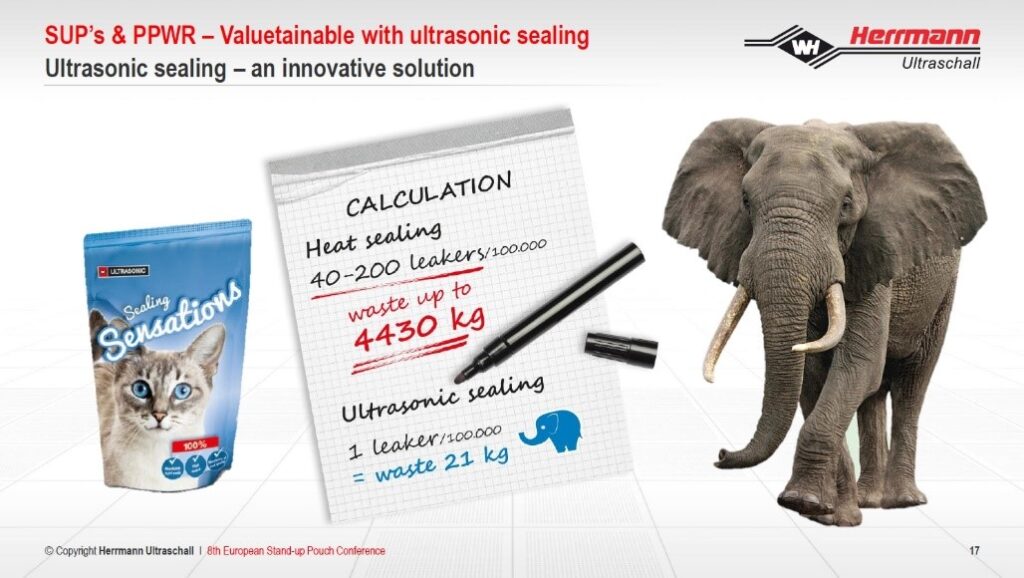

Ultrasonic sealing significantly reduces the number of open pouches in retail, thereby minimizing content loss. (Source: Herrmann Ultraschall)

In his presentation, “SUPs & PPWR – Valuetainable with Ultrasonic Sealing,” Michael Baumann from Herrmann Ultraschalltechnik highlighted the advantages of ultrasonic sealing over heat sealing. Ultrasonic sealing does not thermally affect the contents and, thanks to inline seal quality control, significantly reduces the number of open packages in retail. A key benefit is also reduced material usage due to narrower seal seams, as well as lower energy consumption of the pulsed process compared to continuously heated sealing jaws. According to Herrmann Ultraschall, this reduces energy costs by up to 75%, significantly lowering CO₂ emissions.

Pierre-Emmanuel Grandjean from Bernhardt-Deltasacs outlined the key parameters for enhancing the mechanical durability of pouches, in his presentation “Progress in Improving the Mechanical Resistance of Mono-material PE Pouches and Spouts” New film structures that combine various polyethylene layers improve pouch stability. The patent-pending “Bernhardt Progressive Sealing” system, with specially adapted sealing tools, provides increased seal uniformity and strength. Additionally, an optimized base design was developed for 2-liter doypacks to ensure high impact resistance and stability.

In his presentation ‘The beauty of customised printed stand-up pouches’, Ronny Kunze from Sihl GmbH presented ‘adelmo’, an innovative B2B online platform that simplifies the creation, customization and ordering process for digitally printed stand-up pouches. Adelmo allows customers to create the design of their pouches using a 3D configurator that shows a preview of the designs in real time. The platform meets the demand for pre-made printed pouches with a lead time of a few days in batch sizes of 1 – 50,000 pieces, which is ideal for products that require a fast time to market, limited editions or personalized packaging. He highlighted new business opportunities for local adelmo print partners and their customers in a growing environment.

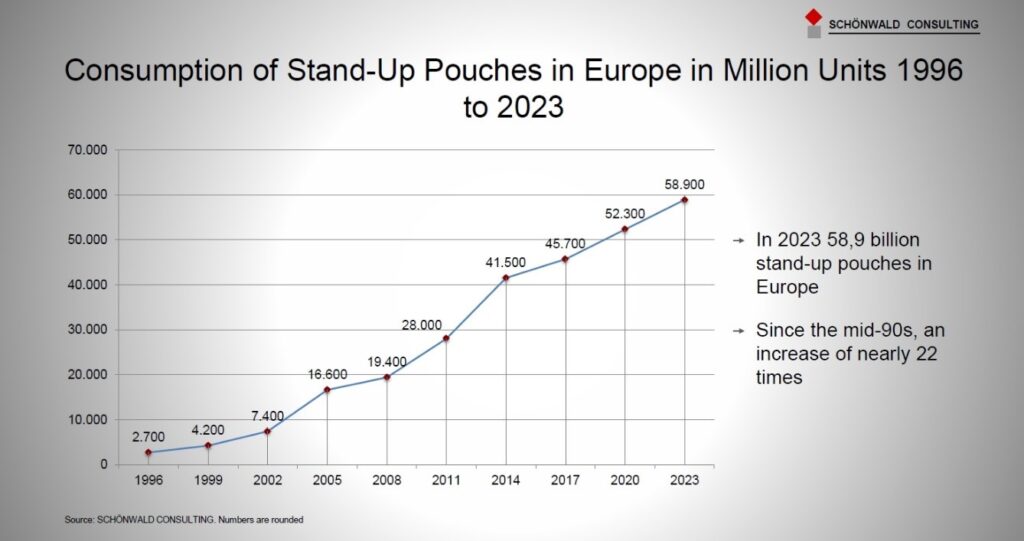

Market development of stand-up pouches from 1996 to 2023 in Europe. (Source: Schönwald Consulting)

In his presentation, “Stand-Up Pouches on the Way to the Future,” Jörg D. Schönwald from SCHÖNWALD CONSULTING discussed the impressive market development of stand-up pouches in Europe, whose usage has increased more than twentyfold from 1996 to 2023, reaching 59 billion units. He analyzed market growth in the segments of food, pet food, beverages, and non-food products, with a growing trend toward pouches with spouts, and examined the laminate materials used. He identified key future drivers for the success of stand-up pouches, particularly in their sustainability, versatility, user-friendliness, consumer acceptance, cost-efficiency, differentiated marketing opportunities, and advancements in production.

Material recycling from the yellow bag mainly takes place with rPET and rHDPE for bottles and tubes. (Source: dm-Drogeriemarkt)

Presenting “Pouches in the drugstore,” Dagmar Glatz from dm-drogerie Markt addressed the market landscape, highlighting where pouches are successful and where they still face challenges. Although dm has converted nearly all pouches to monomaterials and promoted the use of recyclate, a fully recyclable solution is still lacking. Challenges include inks and adhesives that reduce the quality of recycled materials. Additionally, recycled materials remain more expensive than subsidized virgin materials. While the use of rPET and rHDPE is increasing for bottles and tubes, rLDPE from household waste is barely suitable for films, and rPP recycling in this area is nearly nonexistent. Glatz emphasized that technological openness is crucial to finding the most sustainable solution for end-of-life packaging and material reuse in the long term.

In their joint presentation, “Sustainable, Efficient, Successful: Why We Package Our Clean Label Products in Stand-Up Pouches,” Madeline-Marie Fritsche and Mirko Sattler from Bempflinger Lebensmittel GmbH highlighted the environmental benefits of stand-up pouches as an alternative to cans and glass. Production and logistics advantages include space savings, short setup times, and lower packaging weight. Flexibility is evident in customizable design and formats, while user-friendliness is enhanced by unbreakability, light weight, and easy disposal. Market growth is being driven by retailers’ increasing interest in stand-up pouches, which offer advantages in low weight, CO₂ reduction, and cost efficiency.

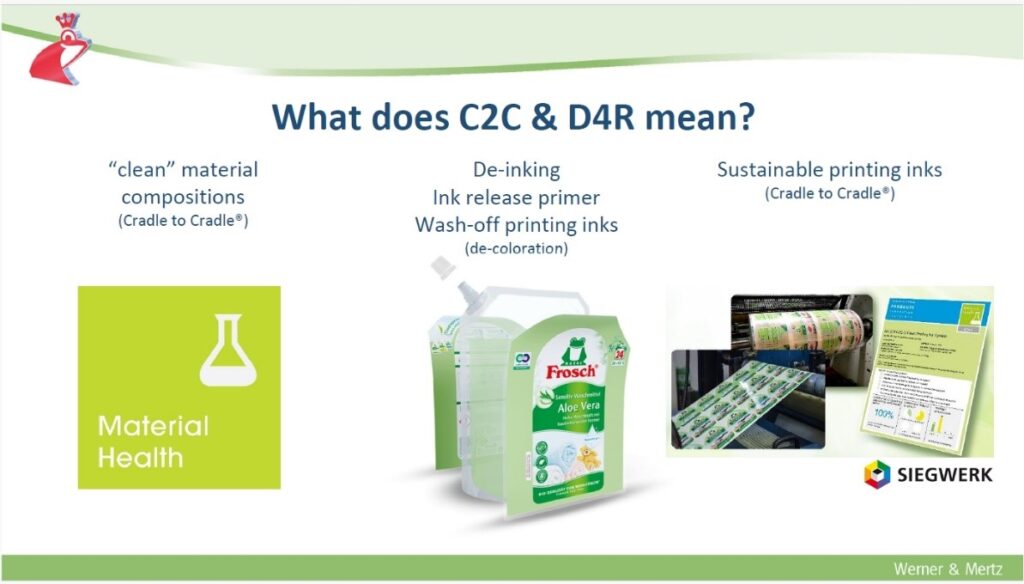

Cradle-to-Cradle and Design4Recycling promote the use of clean material compositions. (Source: EPEA Switzerland)

Albin Kälin from epeaswitzerland explained, in his presentation, “Pouches with Cradle-to-Cradle Certification,” the role of the company as a “Knowledge Trustee” in the procurement of confidential material data and their environmental impact, categorized according to A, B, C, X. Another role of epeaswitzerland is that of an “Innovation Trustee,” where it actively supports companies in networking and developing circular strategies, as well as conducting audits on material health, process design, and the recyclability of packaging. The application of the Cradle-to-Cradle and Design4Recycling principles promotes the use of clean material compositions, removable release coatings, and washable inks. This was demonstrated using the example of the “Frosch Aloe Vera Laundry Detergent” packaging, which is Cradle to Cradle Certified® Gold.

In her presentation, “Sustainability and Technology Combined – Spouts for Stand-Up Pouches,” Lea Middendorf from Pöppelmann FAMAC® introduced resource-saving innovations in spouts, a key component of pouch packaging. For thermal and ultrasonic sealing, Pöppelmann offers spouts with a patented wave structure that protects the film. With low-sealing materials, recyclable mono-material pouches can be created, including PE screw caps. For non-food applications, Pöppelmann uses spouts and caps made from post-consumer recycled materials, emphasizing their commitment to resource conservation and climate protection.

Pierangelo Brambilla introduced Sun Chemical’s Ultra Low Monomer (ULM) product portfolio in his presentation, “New Approaches for the Stand-Up Pouch Market: Sun Chemical’s Integrated Packaging Solutions,”. This proprietary technology focuses on the development of adhesives and coatings with extremely low residual monomer content, offering significant advantages in terms of operator and consumer safety and making it well-suited for recyclable mono-material packaging. By significantly reducing monomer migration from packaging materials into products, the ULM technology enhances food safety and complies with strict regulations. Additionally, it supports the transition to mono-material packaging, such as PE- and PP-based solutions, by incorporating gas barrier properties within the adhesive, making these solutions more suitable for circular economy initiatives.

Karsten Schröder concluded the conference with a concise summary of the presentations. Recyclable monomaterials are essential for sustainable solutions in stand-up pouches, and advancements in barrier technologies are expanding their range of applications. Printing techniques such as digital printing on pre-made pouches enable print runs from as few as 1 piece. Increasingly, premium products use stand-up pouches to present food, pet food, beverages, and cosmetics in a visually appealing and practical way. The growth of online retail further boosts the popularity of this lightweight, durable packaging format. With minimal space requirements and low transport volumes, stand-up pouches are ideal for shipping and offer consumers high functionality and ease of use. Preparations are already underway for the 9th European Stand-up Pouch Conference in two years’ time.

Further information and access to the lecture recordings is available at: innoform-coaching.de/en/tagung/8th-european-stand-up-pouch-conference-easy-to-use-2024