Flexpack NEWS

Current topics and trends

The Innoform blog/news offers in-depth insights into the world of flexible packaging (#Flexpack). Our articles range from sustainable packaging solutions to innovative film packaging technologies and regulatory challenges. Expert interviews, market assessments and news from the industry round off the offer and keep packaging professionals up to date. Discover how we are shaping the future of the packaging industry through continuous learning and exchange.

-

Dieter Niederstadt: Fully automated water-washable flexographic plates and assembly

In the latest Innoforum podcast, Karsten Schröder talks to Dieter Niederstadt from Asahi during the 10th Packaging Printing Expert Meeting Inno-PrintPack about a topic that has been preoccupying flexographic printers for years: How can quality, productivity and sustainability be reconciled in printing plate production? Asahi relies on water-washable flexographic printing plates and a comprehensive “AWP…

-

Inno-Talk: Data-driven Design for Recycling in Flexible Packaging

This InnoTalk episode—an initiative by Innoform Coaching—featured Haulwen Nicholas (CEFLEX) and was moderated by Guido Aufdemkamp (Flexible Packaging Europe, FPE). (CEFLEX) Flexible packaging delivers strong resource efficiency and product protection, but it remains challenging to sort and recycle at scale—especially when structures include multiple layers, inks, coatings, adhesives, and functional barriers. CEFLEX addresses this gap…

-

Inno-PrintPack 2025

Two days, five trends, one goal: to make packaging printing efficient and recyclable. The 10th Packaging Printing Expert Meeting impressively demonstrated how modern technologies, from 7C fixed palettes and AI-supported real-time data analysis to robotics, inline inspection, anti-counterfeiting measures and recycling-friendly materials, are transforming production processes in a sustainable way. Dieter Finna The “Expert Meeting…

-

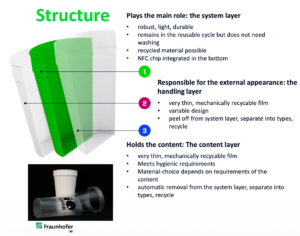

Reusable packaging reinvented: How IQ*Pak makes the cycle more efficient

IQ Pak: Separation of system components and hygiene functions The core of the concept presented consists of consistently separating the ‘reusable component’ – i.e. the durable system carrier – from the functional layers that come into contact with the product and the consumer. Put simply, the packaging consists of several layers: Systemlayer: Contentlayer: Handlinglayer: The…

-

When is packaging considered reusable?

Reuse in the focus of the PPWR The EU Packaging Regulation (PPWR) asks a key question for the industry: When will packaging actually be considered reusable in future – and what requirements are necessary for this?Inno-Talk highlighted the most important points relating to the term “reuse”. This blog post summarises the key messages in an…

-

Web seminar – Highlights: Japan Food Sanitation Act

1. Positive lists and new requirements since 2023 Since June 2025, the revised positive list system for plastics and additives has been in force in Japan. That means for packaging manufacturers and packers that only raw materials listed in the current lists may be used. It is particularly important to distinguish between the previous (2019)…

-

37th Inno-Talk: Monomaterial FFS Packaging

Yair Gellis – MDO-PE as a building block for FFS packaging made from a single material In his presentation, consultant Yair Gellis highlighted the potential of MDO-oriented polyethylene films (MDO-PE). Dr Anina Leipold – Efficient processing of monomaterials and paper on VFFS machines: challenges and solutions Dr Anina Leipold from Rovema highlighted the machinery and…

-

Inno-PrintPack 2025 at Follmann – Experience packaging innovations live

Hasbergen/Minden, 28 August 2025 – The renowned „Expert Meeting Packaging Print“ enters its 10th edition under a new name: Inno-PrintPack 2025. On 27 and 28 November 2025 the packaging print industry meets at the new event center of the Follmann Group in Minden – for the first time in the middle of a speciality chemicals…

-

Flexible packaging in environmental testing: plastic or fibre (paper)?

A key question for all those responsible for packaging is currently: How can the overall environmental damage caused by packaging be minimised? Flexible packaging is already considered a resource-saving solution, as it requires less material than rigid formats. However, the specific choice of materials has given rise to new discussions: plastic versus fibre, mono versus…

-

The future of recycling: How new technologies are making flexible packaging sustainable

Flexible packaging – such as crisp packets, films and stand-up pouches – have become an integral part of our everyday lives. However, recycling it poses a major challenge. The European initiative CEFLEX has set itself the goal of overcoming this challenge and establishing a functioning circular economy for flexible packaging. Why new technologies are necessary…

-

How Romania is becoming a test area for the recycling of flexible packaging

1 | What is “RoFlex”? The industry initiative CEFLEX (Circular Economy for Flexible Packaging) launched the pilot project “RoFlex” (Romania Flexible Packaging Recycling Pilot) in Romania in mid-July. Together with local collection, sorting and recycling companies as well as brand owners, a complete value chain for flexible plastic packaging is to be established there for…

-

Summary: Barrier Laminates – Expert Meeting 2025

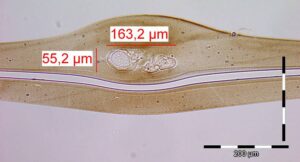

The two-year conference at the SKZ-Modellfabrik Würzburg on 1 and 2 July 2025 offered a comprehensive insight into current developments and trends in barrier laminates. The focus was on new material solutions and innovative manufacturing processes for monomaterials. In addition, the performance of modern films was impressively demonstrated and precise measurement methods for permeation measurement…

-

When the bubble ticks

Typical error patterns in blown film extrusion and what you can do about them In blown film extrusion, all it takes is a small irregularity and a defect will spread over the entire length of the roll – including expensive scrap metres. We have summarised the most common defect patterns so that you can link…

-

The plastic revolution – turning waste into bioplastics

Listened to & summarised from the SWR podcast ‘Das Wissen – Die Plastikwende: How can plastic become sustainable?’ with chemist Dr Manuel Häußler (Max Planck Institute/CTC, founder of EvoLoop). 1 | Why we need to rethink plastic Plastic is light, robust and extremely cheap – which is precisely why it is conquering every market segment.…

-

PET bottle, beverage carton or pouch – which is the ultimate recycling champion in the EU?

An attempt to compare costs and recyclability Packaging for water and other beverages is increasingly at the centre of the sustainability debate. This not only raises the question of production costs, but also recyclability and practical implementation in various EU countries. In this specialist article, we compare PET bottles, beverage cartons and pouches in terms…

-

New study highlights challenges and potential in recycling flexible plastics

In a recent study, CEFLEX and Ghent University investigated the challenges and potential of new recycling technologies for flexible plastics. These technologies include delamination, deinking, dissolution and contaminant extraction and aim to meet the requirements of the Packaging and Packaging Waste Directive by 2030. Technology selection and capacity assessment The study analysed twelve technology providers…

-

Call for Papers – 10th Expert Meeting Packaging Printing 2025

Call for Papers – FlexPack Print 2025 Your technical contribution for the 10th Expert Meeting Packaging Printing “Efficient and recyclable” Date: 27-28 November 2025|Location: Follmann Technology and Knowledge Centre, Minden (DE) InnoMeeting Why take part? Circular economy, mono-materials, deinkable colours and short-run workflows – the pressure for change in packaging printing is increasing rapidly. At…