Two days, five trends, one goal: to make packaging printing efficient and recyclable. The 10th Packaging Printing Expert Meeting impressively demonstrated how modern technologies, from 7C fixed palettes and AI-supported real-time data analysis to robotics, inline inspection, anti-counterfeiting measures and recycling-friendly materials, are transforming production processes in a sustainable way.

Dieter Finna

The “Expert Meeting on Packaging Printing” celebrated its tenth edition under the new label “Inno-PrintPack” and offered another novelty. The symposium was held from 27 to 28 November 2025 in the newly built event centre of the Follmann Group in Minden, in the middle of a speciality chemicals factory. The modern infrastructure of the technology and knowledge centre provided ideal conditions for in-depth specialist presentations and further exchange.

Michael Weihing from GMG highlighted the paradigm shift from printing with special colours to four to seven process colours. This approach increases efficiency in the print shop by up to 27% thanks to shorter set-up times and less waste, as he demonstrated in a practical example. Savings of up to €337,000 per year can be achieved in the example case, with an additional order potential of €5 million per machine. In addition, standardised processes increase the repeatability of print results and sustainability in terms of CO₂ balance. Added to this are greater standardisation, which strengthens brand loyalty, enables greater flexibility in order sequencing and leads to faster delivery times.

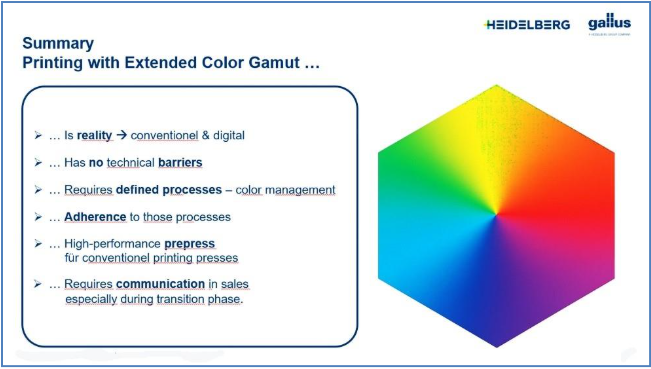

Requirements for switching to extended process colours. (Source: Gallus Ferd. Rüesch AG)

Uwe Alexander from Gallus presented the advantages of 7C printing in the label sector: significantly fewer colour changes, shorter set-up times, reduced washing cycles and the possibility of producing several jobs in one run using combination forms.

At Permapack AG in Switzerland, the 7C workflow was put into practice after software adjustments and optimised processes. Due to the order structure with a high proportion of digital printing and the decision not to use 7C in the cosmetics segment, the proportion of potential 7C orders is below original expectations – however, the decision to use 7C printing would be made again. The approach is particularly convincing in digital printing: the break-even point compared to conventional printing rises from the often-cited 2,000 to 10,000 linear metres.

In his presentation “Anilox Rolls in 7C Printing,” Jörg Rohde from Zecher showed the way to a lean, clearly specified range of anilox rolls with defined volume levels for printing in an extended colour space. Zecher provides targeted support to users in specifying anilox rolls – tailored to the printing plate screen, plate surface, ink type, substrate and engraving form. Special engravings such as SteppedHex with elongated cells enable higher lineatures with the same volume and thus optimised ink transfer. A standardised roll inventory reduces set-up times and risks. Regularly documented cleaning and maintenance ensure colour density, high transfer quality and process stability in 4C/7C printing.

Alexander Sailer from manroland Goss showed how a central data platform in web offset packaging printing creates real-time transparency regarding energy, material and media consumption. This is analysed per order, product or over a defined period of time. Automatically recorded machine and sensor data enable quick decisions, lead to less waste and prevent downtime through preventive maintenance. Clearly laid out dashboards make key figures and deviations immediately visible and tangible, facilitating comparisons between orders and locations. This reveals potential savings, determines the optimum production speed, makes processes more stable and increases overall equipment effectiveness (OEE). All this with open interfaces for your own IT systems.

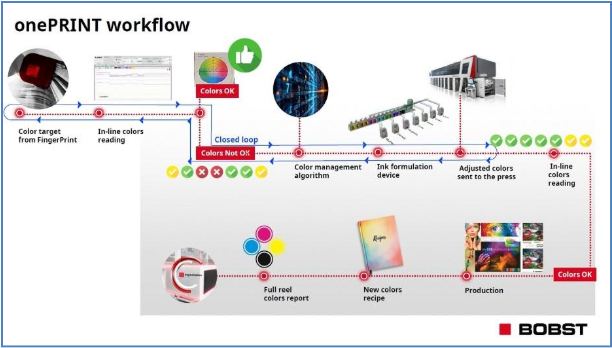

onePrint ensures consistent colour in the gravure printing process. (Source: Bobst)

In his presentation, Marco Schmidt from Bobst outlined the advantages of the smartGRAVURE system, which consistently digitises the gravure printing process without compromising the traditional quality strengths of the process. While conventional gravure printing is characterised by analogue set-up processes, numerous special colours and a high degree of operator dependency, smartGRAVURE brings efficiency and stability to the process. The extended oneECG (7C) colour spectrum reduces the number of special colours and allows 95% of the Pantone colour space to be reproduced. The oneSET digital job preparation system supports the operator at the machine by reducing set-up times, while the onePRINT inline measurement system guarantees consistent colour. Overall, this new concept leads to a significant increase in efficiency in gravure printing . Comprehensive data connectivity with BOBST Connect enables transparent process monitoring and in-depth production analysis.

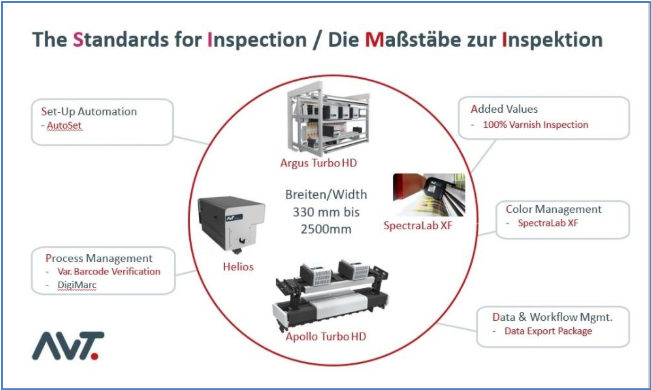

Inspection systems offer 100% print defect and coating control (source: AVT)

Tarik Sevinc from AVT showed how modern inspection systems define production reliability. They offer seamless, 100% print defect and coating control across the entire web width in real time – from register and print quality deviations to barcode checks. As high-speed solutions, they are available for both narrow web applications and label printing. In addition, inline spectral colour measurements via SpectraLab XF ensure reproducible colour consistency for every job. Comprehensive data management guarantees that all production and error data is digitally documented, ensuring traceability and enabling targeted process optimisation.

Allstein Robotics transfers the cut plates to the automated assembly line. (Source: Allstein)

Dr Thomas Klein (Esko-Graphics) and Dr Dieter Niederstadt (Asahi) presented a collaborative project in which Esko, Asahi, Kongsberg and Allstein demonstrated for the first time a fully networked and automated workflow from flexo master plate to finished print in practice. The AWPTM water plates with short processing times are imaged on a CrystalCleanConnect system with a Q-cells surface structures at 4000 ppi and processed extremely quickly thanks to 90% less operating effort. Allstein robotics transfers the cut plates to the automated mounting system and on to the automatic loading of the Genesis flexographic printing press. The result of collaborative automation: an enormous leap in productivity, maximum process consistency and first-class print quality – already commercially available.

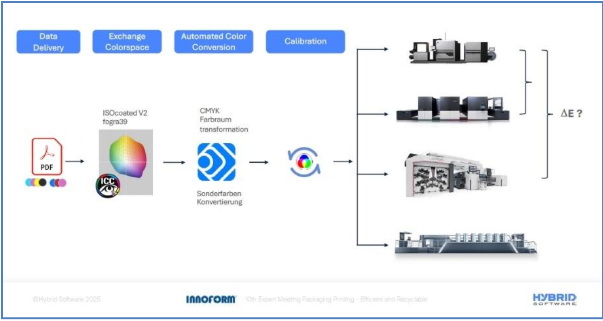

Colour management for printing with extended colour space (source: Hybrid Software GmbH)

Victor Asseiceiro from Hybrid Software presented “7C printing and fixed palette workflows – ECG implementation for analogue and digital printing technologies” and showed that successful printing with an extended colour gamut is based on standardisation towards a consistent 7-colour process and a predictable ∆E. Digital printing is changing the value chain: data preparation and colour management must be carried out in the print shop. This significantly increases overall equipment efficiency and achieves annual cost savings per machine. The key is the seamless integration of colour management into the ERP system and prepress automation via open interfaces. The technology is ready – digital ECG will drive analogue adaptation forward.

Yair Gellis addressed the challenge posed by MDO-PE as a highly recyclable monomaterial in the printing process. MDO-PE film has very low surface energy, is sensitive to heat and exhibits a strong memory effect – factors that make ink adhesion, register stability and flatness difficult. For reliable ink adhesion, a corona refresh in the printing press to around 42 dynes/cm is essential. The temperature in the drying channel must be below 85 °C to prevent warping. A low web tension of 0.8–1.2 N/cm stabilises the register. Different film qualities require Standard Operating Procedures (SOPs), and both ink and composite adhesion must be carefully checked for laminates.

Types of defects detected in film production (source: OCS Optical Control Systems GmbH)

In his presentation, Oliver Hissmann from OCS Service demonstrated how modern inspection systems also ensure the quality of recycled films and new “green” polymers. The high-speed FSP600 web system uses combined transmission and reflection measurement ( ) as well as bright and dark field illumination to detect defects such as gels, specks, craters, holes or coating defects in real time – and all this on coloured or transparent films. Multi-Channel Evaluation (MCE) prevents false alarms, especially with PCR films, which have a high level of material noise. Up to six channels distinguish relevant defects from background noise. The defects are differentiated and finally classified by an automatic classifier after the defect has been taught to the system.

André Altevogt from Follmann first addressed the stricter limits for heavy metals and PFAS applicable to printing inks, which will apply to packaging materials from 2026 as part of the PPWR. In his core message, he emphasised that Follmann water-based inks are 100% water-based, virtually VOC-free (< 1%) and do not interfere with the recycling process if they account for less than 5% of the packaging weight. Technically, water-based inks enable high colour strengths, fine screens and printing speeds of up to 800 m/min. Case studies show a significant reduction in total costs for the same ink volume, despite higher cleaning costs. This is due to lower costs for inks and solvents.

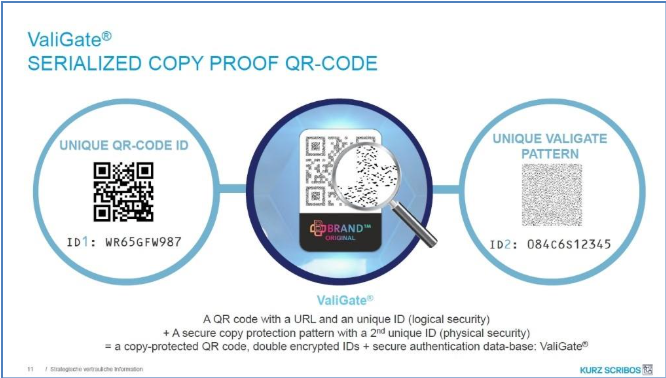

From QR code to copy-protected, individualised QR code ValiGate® (Source: SCRIBOS GmbH)

The presentation by Dr Steffen Scheibenstock, SCRIBOS GmbH, focused on the growing global counterfeit market and the brand and product protection solutions offered by KURZ SCRIBOS. The most effective method of protection is to involve the customer in the authentication process. KURZ SCRIBOS offers the ValiGate®technology for this purpose. This is a serialised, copy-protected QR code with double encryption and a physical protection pattern. On packaging, this counterfeit-proof solution enables verification via smartphone without a separate app, confirming authenticity or revealing the product as a counterfeit.

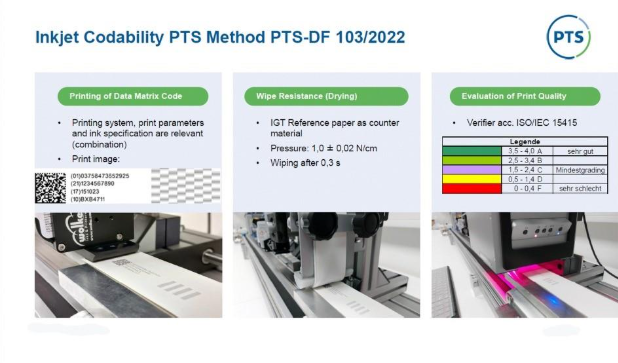

The cardboard qualities are tested for codability using standardised PTS methods. (Source: PTS – Institut für Fasern & Papier gGmbH).

Nicole Brandt from PTS – Institut für Fasern & Papier gGmbH – addressed

the requirements of EU Regulation 2016/161 for the effective prevention of counterfeit medicines for human use. She then continued her presentation with a focus on pharmaceutical applications. The core requirement is seamless end-to-end verification using individual data matrix codes (minimum print quality of 1.5 according to ISO/IEC 15415) and tamper protection, for example through a tamper-evident label. The necessary checks for codability (inkjet/laser) and the durability of the codes over 5 years are carried out according to standardised PTS methods.

In his presentation, Dr Sven Macher from VP Medical Packaging illustrated how low-migration UV printing inks contribute to the safe packaging of sensitive medical products. The focus is on patient safety and standard-compliant manufacturing (including ISO 13485). He discussed the requirements of PPWR, MDR and ISO 11607 for packaging materials and printing inks with regard to sterilisation compatibility, toxicological evaluation and extractables and leachables analyses. Based on migration studies of various UV ink systems, test setups, analytical methods, limit values and measurement results were presented to evaluate suitability for medical packaging.

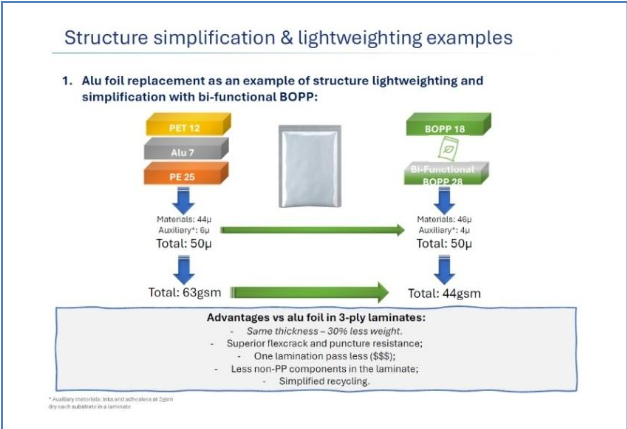

By simplifying laminate structures and reducing weight, BOPP is actively promoting the recyclability of packaging films. (Source: Transparent Paper Ltd.)

Marcin Lapaj from Transparent Paper Ltd. gave a presentation on the transition from BOPP films to PPWR-compliant monomaterial structures. The focus is on innovations such as BOPP films with ultra-high barrier properties (UHB), which replace aluminium foil in multi-layer laminates for dry and moist food applications, as well as bifunctional hybrids that combine good sealing properties with ultra-high barrier properties. Heat-resistant (HR) BOPP films with controlled shrinkage also ensure dimensional stability on high-speed packaging machines. By reducing weight with low-density matt BOPP films and simplified laminate structures, BOPP actively promotes the circular economy and meets the PPWR requirements for mono packaging.

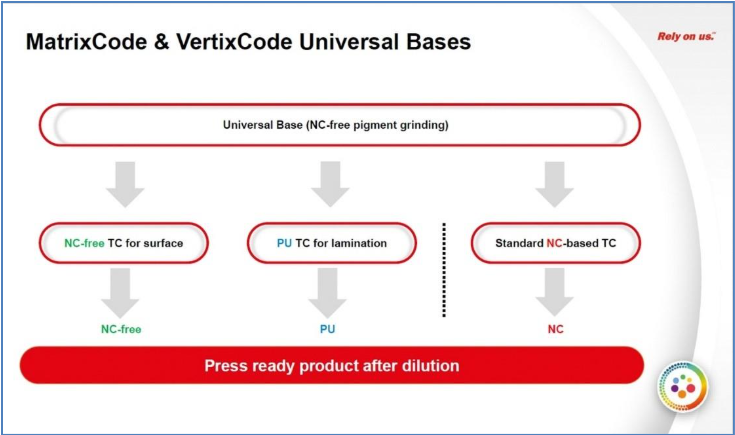

PU-based, NC-free and NC-based printing inks for front and reverse printing are produced from a range of universal bases. (Source: Flint Group)

Dr Ricarda Hofmann from Flint Group addressed the stricter requirements of EU recycling legislation (PPWR) for print-friendly, recyclable inks. Flint Group is responding with innovative universal bases (NC-free pigment grinding) that cover the entire packaging spectrum from paper to polyolefin, polyester and polyamide films. These adapted, solvent- and water-based ink systems reduce complexity in the print room and ensure compliance with regulatory standards.

Attilio Borlenghi from Sun Chemical presented Ultra Low Monomer (ULM) laminating technology, which complies with new EU and US regulations for food safety and occupational health and safety. Newly developed ULM adhesives with less than 0.1% diisocyanates significantly reduce the necessary curing time after lamination thanks to their extremely low residual monomer content. A high-performance ULM variant is available for retort applications. The solvent-free, RecyClass-certified SunLam adhesives, Paslim barrier laminates and SunBar barrier coatings form a modular product portfolio that enables the switch to recyclable mono-material packaging. These adhesive systems comply with food law requirements immediately after lamination.

Karsten Schröder concluded Inno-PrintPack with a concise summary of all the presentations. The presentations clearly demonstrated how relevant the topic of 4C/7C fixed palettes has become, with their efficiency gains in packaging and label printing. They also highlighted the scale of innovation in AI-supported real-time data analysis, the use of robot-controlled systems and inline inspection.

Anti-counterfeiting technology is constantly evolving and is being effectively implemented through authentication processes. At the same time, the PPWR is driving forward the development of recycling-friendly packaging materials – with a noticeable impact on ink systems and laminating adhesives. This year’s Inno-PrintPack expert meeting once again highlighted how dynamically the packaging printing industry is continuing to develop.

Further conferences on flexible packaging can be found here and technical articles at: https://inno-talk.de/news/

Leave a Reply