IQ Pak: Separation of system components and hygiene functions

The core of the concept presented consists of consistently separating the ‘reusable component’ – i.e. the durable system carrier – from the functional layers that come into contact with the product and the consumer.

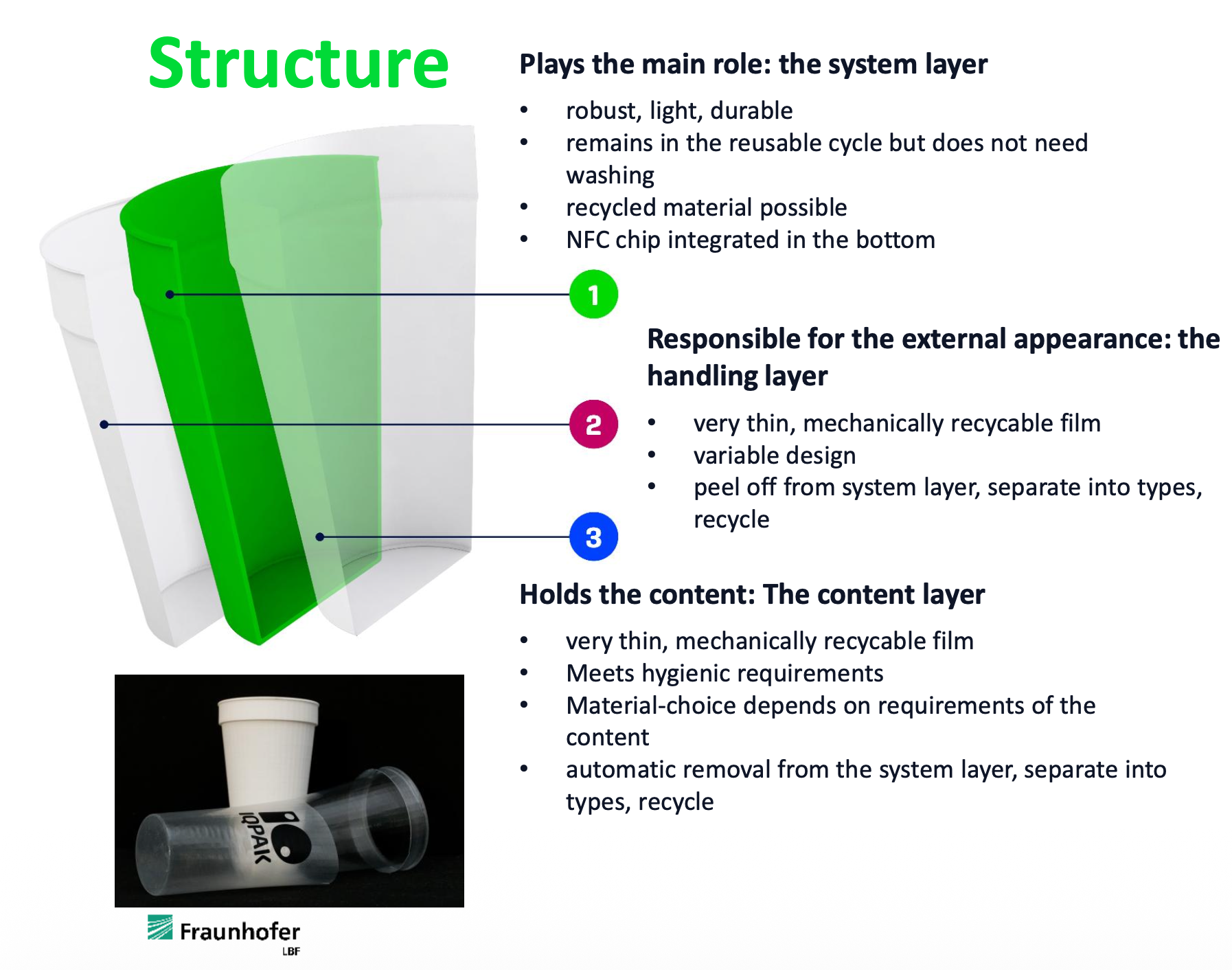

Put simply, the packaging consists of several layers:

Systemlayer:

- Robust, durable structure

- Forms the actual reusable ‘framework’ (e.g. cup or tray)

Contentlayer:

- Layers that interact directly with the filling material (e.g. barriers, sealing media)

Handlinglayer:

- Outer layer that the consumer comes into contact with

- Conveys feel, look and brand image

- Can be applied using thermoforming or sleeves, for example

The key point: the reusable component remains protected from the inside and outside by the hygiene layers. Contamination, product adhesion or visual wear mainly affect the replaceable layers – not the durable system layer.

Less washing, more cycles

Because the system layer is shielded by a hygiene layer, traditional intensive washing processes can often be dispensed with or significantly reduced. Instead, after return, the thin functional layers are removed and sorted by type.

Advantages of this approach:

- Reduced water, energy and chemical consumption

- Less mechanical stress on reusable components

- Longer service life of the system layer and thus more cycles per unit

- More flexible transition to new designs, decors or regulatory requirements

Separating the system and function layers allows the reusable pool to be kept small, standardised and efficient – while at the same time allowing the brand, decor or product-specific properties to be reconfigured in each processing cycle.

Digital traceability via NFC

Another component of the IQPak system is the digital registration of each individual package.

- Each unit is equipped with an NFC chip.

- The chip links the physical packaging to a data record in the central database.

- This data record can be used to display the following information, among other things:

- Number of cycles

- Status in the cycle (in use, in return, in processing)

- Assignment to specific customers, pool operators or applications

- Recycling paths and sorting information for the removed layers

This results in several added benefits for pool system operators:

- Greater transparency regarding stocks and circulation figures

- Better control of logistics and returns

- Sound data basis for life cycle assessments and reporting

Design freedom despite standardisation

A potential conflict of objectives in reusable systems is the tension between standardisation and brand identity: the more uniform the shapes, the more efficient the logistics – the more individual the design, the more a brand can differentiate itself.

IQPak attempts to resolve precisely this tension:

- The system layer remains largely standardised in terms of shape and basic geometry.

- The handling layer and the outer functional layers offer a wide range of design options: colours, printed images, haptics, brand claims.

- These outer layers can be re-selected for each preparation – without enlarging the pool itself.

This combines standardised reusable carriers with individual branding.

Fields of application: from food to non-food

In the transcript, the system is demonstrated using the example of a cup, which is particularly suitable for food and beverages. However, the approach can essentially be applied to various geometries and filling materials – whenever:

- high hygiene requirements apply,

- many cycles are economically viable, and

- a standardisable reusable carrier is to be combined with changing requirements.

Conclusion. Reusable packaging taken to the next level – technically and digitally

The IQ Pak concept shows how classic reusable systems can be further developed with the help of layer construction and digitalisation:

- The system layer is consistently protected, thereby maximising its service life.

- The hygiene layer and handling layer take on the ‘consumption-intensive’ functions – including design, product protection and consumer communication.

- Digital identification via NFC opens up new possibilities for cycle control, reporting and recycling quality.

For companies that want to make reusable strategies sustainable in line with economic and regulatory requirements, it is worth taking a look at such modular, data-based systems. In our formats at Innoform Coaching, we accompany these developments and discuss them with experts.

Leave a Reply