Have we already decided which side we are on in the “packaging war”? Do not worry, at Innoform we prefer to look at the whole thing with a pinch of humour and a healthy dose of data. Will our beloved biscuits be wrapped in high-tech film or stylish barrier paper in 2026?

Here is a fresh look surrounding fibers vs. polymers – straight from the digital rumour mill of our AI analyses. We discuss fundamental trends based on a model calculation to kick off the next expert discussion.

The duel: 1 kg of biscuits – who will win the race?

Cookies are divas. They want it dry, they want it greasy (but only on the inside!) and they hate foreign odors. While the plastic faction relies on slim monostructures, the paper faction brings out the big guns when it comes to coating.

The quick check in comparison

| Feature | The thin film (mono-PE or PP) | The fancy paper (barrier) |

| Fighting weight | approx. 18 g (lightweight) 100 micron | approx. 50 g (heavyweight) 250 g/m2 |

| Superpower | MDO Technology | Renewable fibers |

| Recycling-Vibe | Circulation-ready | Waste paper favorite |

| Trend factor | Digital Sealing Precision | Natural “eco-look” |

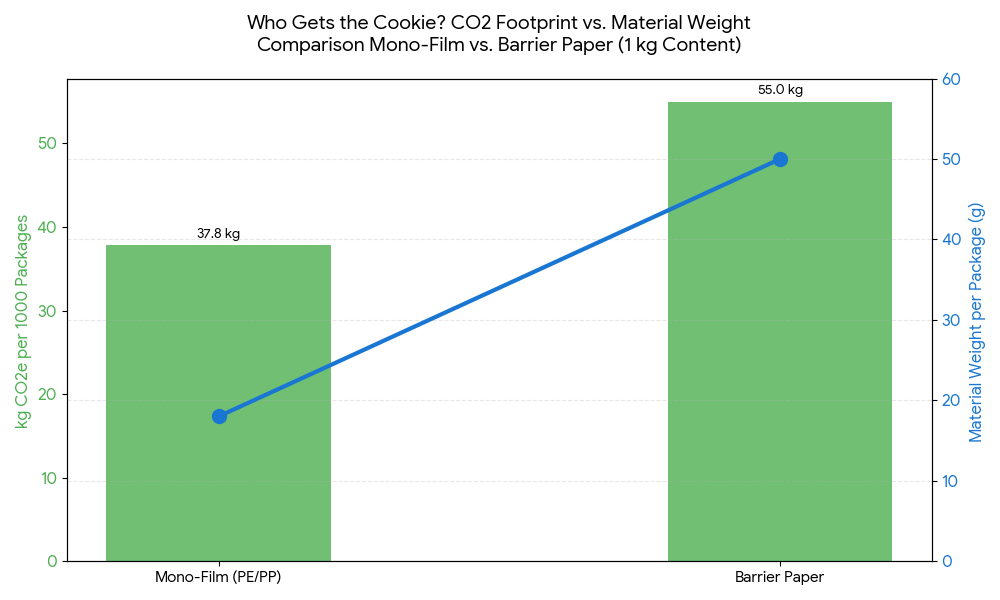

The carbon footprint: When weight crashes the party

This is where it gets “capricious”: we all love paper because it smells like the forest and is renewable. But—and this is a big but—for 1 kg of cookies, paper needs to be quite thick (approx. 80 to 110 g/m²) so that it does not collapse at the first gust of wind.

(The graph shows: The feather-light mono film often comes out ahead in terms of CO2 balance per 1000 packages, simply because it weighs so damn little! Despite its better footprint per kg of material, paper has to carry more “CO2 baggage” due to its high grammage.) These are merely fictitious assumptions intended to illustrate the influence of weight.

What is really going on in the flexpack jungle in 2026

No matter which team you cheer for, the technology is running at full speed:

- Paper machines on steroids: Mondi has launched a paper machine in Štětí that takes flexible paper solutions for e-commerce and more to a new level.

- The barrier whisperers: Start-ups such as one.five show that paper can also play a role in confectionery thanks to smart coatings.

- Film is becoming even thinner: Thanks to MDO-PE modular systems, plastic is becoming so efficient that it is almost uncanny.

- Digital sealing: To ensure that the seam holds, precise sealing ensures that no air escapes from either the film or the paper.

- Rules, rules, rules: The PPWR and the new CO2 reporting obligation starting in January 2026 ensure that we all have to do our homework when it comes to recycled content quotas.

Conclusion: Who gets the cookie?

There is no knockout victory—it is a marathon. If you are looking for minimal material use and the best CO2 values in production, mono film remains your best friend. If the “end-of-life” feeling and renewable sources are more important to you, paper is your star.

Keep in mind: This is an AI-based trend calculation. For real decisions, you will of course need a rigorous LCA for your specific product.

More perspectives and fillers will follow if you recommend us to others and we receive positive feedback—otherwise, that is it for today.

If you want to know more and need to know more, do not miss INNO-Fiber.

List of sources

- Inno-Talk Podcast & News: Current insights into the world of flexpack.

- Digital Sealing: Precise sealing for mono-materials.

- Material innovation: MDO-PE modular system according to Prof. Achim Grefenstein.

- Industry news: Mondi Werk Štětí, start-up of the new paper machine.

- Cooperations: one.five and Barsch for sustainable paper solutions.

- Regulations: Focus on PPWR and recycling rates.

- Market data 2026: Carbon reporting and economic trends.

Leave a Reply