PP stand-up pouches vs. PET bottles for high-quality and sensitive fillings – a report by Dr. Bernd Knierbein

As by January 2026, part 3 from 5, part 2 here:

3. Completion of packaging, filling, and sealing processes

3.1 Processes for Stand-up Pouches

3.1.1 Sealing the spout

The pre-made flat bags (see section 2.2.1.) can be loaded into the machine for sealing the spout as a stack or as a Leparello and fed into the system.

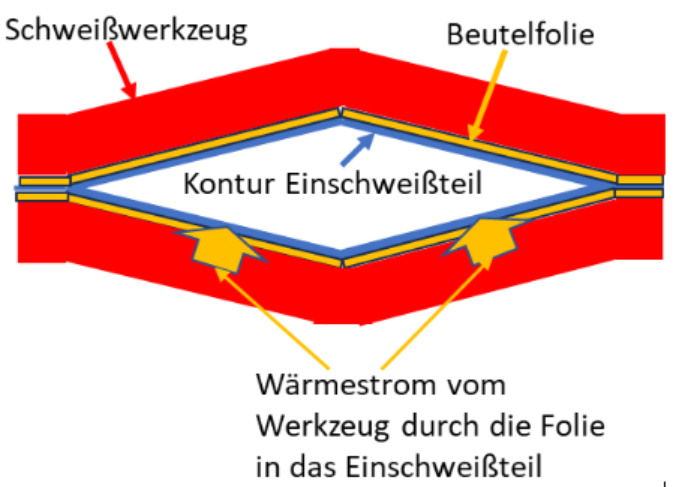

Figure 3.1. Heat flow during welding of the spout

Sealing the spout into the flat bag is an extremely critical process for the following reasons:

- The spatial spout with boat inevitably distorts the flat bag.

- With conventional welding processes, the welding heat can only be transferred from the outside through the entire bag film composite to the outer welding surfaces of the boat (see figure 3.1).

- The composite structures with PET in the outer layer that have been common up to now generally allow for harder welding conditions than welding into a pure PP composite.

These constraints result in longer welding times, which must be achieved by means of several stations in succession. Furthermore, cooling is also necessary at the end of the welding process to stabilize the seam.

After welding, it is also advisable to allow the weld to recrystallize before higher loads are applied to the welded joint during the filling process with the bag hanging from the spout.

Faster welding is generally possible with ultrasound /19/, but this is not yet widely used. The fundamental advantage here is that the heat does not have to be introduced into the welded part from outside through the films, but is generated in the joining zone by the selected excitation.

Leak tests are complex due to the risk of microleaks (in the µm range), especially in the weld seams, which are permeable to bacteria.

3.1.2 Filling process through the spout

During the filling process, it must be ensured that the bag unfolds safely and quickly when the filling material enters. Both the position of the spout in the bag and the adhesive forces of the bag films still lying on top of each other contribute to this.

3.1.3 Sealing process

After filling, the bag is closed at the spout using suitable closures such as screw caps, welded caps, or snap caps.

The filled and closed bag can then be fed to the next line stations, such as final packaging or further heat treatment.

3.1.4 Filling through the open end of the bag

If larger filling openings are required, it is advisable to fill through the upper open end of the bag, then tighten the head seam and seal it by welding. This is necessary for chunky fillings such as pet food or sauerkraut. The disadvantage is that it may be necessary to weld through the product /20/.

3.1.5 O2 barrier of film and pouch

The O2 barrier of high-quality ceramic-coated films is 0.1 cm3/m2 d bar for 100% O2 /21/. The film surface area of a 500 ml bag is approximately 0.06 m2, which results in a theoretical OTR value of 0.006 cm3/pack. This value deteriorates due to

- the structurally necessary kink in the bottom fold,

- the spout, if there is no gas barrier there,

- the polyolefin weld seams,

- the sterilization process.

3.2 Processes for the bottle: injection stretch blow molding of the bottle with coating, filling, and sealing

3.2.1 Stretch blow molding process for bottles with integrated leak testing for the bottle body

The two-stage stretch blow molding process has become established for high output rates, as the injection molding and stretch blow molding processes can be optimized independently of each other.

Detailed descriptions of all process steps are provided in the reference book Blow Molding of Plastic Hollow Bodies /6/.

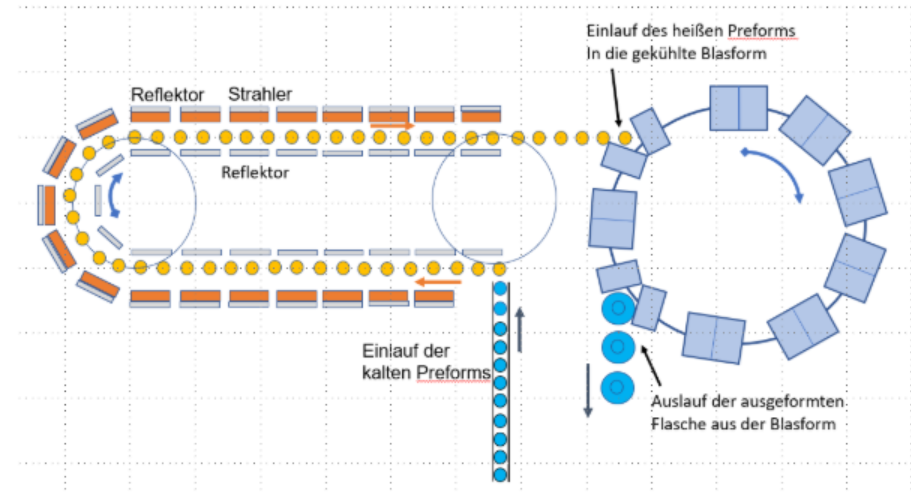

In the two-stage injection stretch blow molding process (second heating process), the PET preforms are treated as follows (see figure 3.2):

- Introduction of the cold preform as bulk material into a bunker

- Introduction into the blow molding machine via vibrating pots and sections

- Heating in a heating section with radiant heaters, during which the preform rotates for even heating (for rotationally symmetrical bottles)

- The outer layers of the preform must be cooled by fans to prevent overheating so that the critical stretching temperature can be reached on the inside.

Figure 3.2. Heating of the preform and blowing into a bottle during the stretch blow molding process /6/

In the second part of the machinery, the suitably preheated preforms are blown into their final shape (see figure 3.2):

- The heated preform is placed in the open blow mold, which is then closed.

- The preform is pre-stretched lengthwise using a stretching rod.

- The bottle is then blown into the tempered mold using high blowing pressure (up to 40 bar).

- After the blowing process, the bottle can be removed from the mold and fed into further processes by means of neck handling.

3.2.2 Further barrier improvements to PET bottles through inner coatings

Biaxially oriented PET already offers good gas barrier properties, but these can be significantly improved by applying coatings, preferably on the inside.

SiOx interior coatings are possible for up to 48,000 bottles/hour /9/, alternatively, carbon coatings are also available /10/. The layer thicknesses are very low, in the range of < 100 nm.

Barrier of the coated PET bottle without cap for 0.21%O2:

The BMBF report for ketchup /23/ specifies OTR values of up to 0.004 cm3/pack day.

A comparison with the bag barriers in section 3.1.5 shows that the magnitude of the OTR values are similar for both types of packaging.

The effective bottle barriers depend heavily on the PET wall thicknesses and the bottle geometry and must always be determined individually.

3.2.3 Aseptic filling

- Pre-sterilization of the liquid product using an UHT (ultra-high temperature) system

- Pre-sterilization of the packaging components using H2O2

- Combination of the pre-sterilized product and the pre-sterilized packaging components

- Filling and sealing in the system under aseptic conditions

Filling speeds of up to 36,000 bottles/hour are achieved here /24/

Figure 3.3. FBL aseptic filling system for PET bottles /24/

Ein anderer Maschinenersteller kombiniert die Streckblasmaschine blockweise mit einer aseptischen Füllanlage /25/.

3.2.4 Sleeving the filled bottles

In order to achieve a presentation area comparable to that of a bag, sleeving the entire bottle body is a good option for bottles /26/:

- The sleeve is produced as a single-layer film by extrusion followed by stretching, usually from PET or polyolefins with thicknesses of approx. 30 µm.

- This film is printed by the converter using flexographic printing or, for short runs, digital printing, and welded lengthwise to form a tube.

- The filled bottle is then wrapped in the sleeve tube, which is cut to length and then passed through a heated shrink tunnel with the bottle so that the sleeve fits snugly around the contours of the bottle.

Alternatively, direct printing /27/ or labeling with adhesive labels are also conceivable for PET bottles; however, from a recycling perspective, the easily separable sleeve offers advantages here.

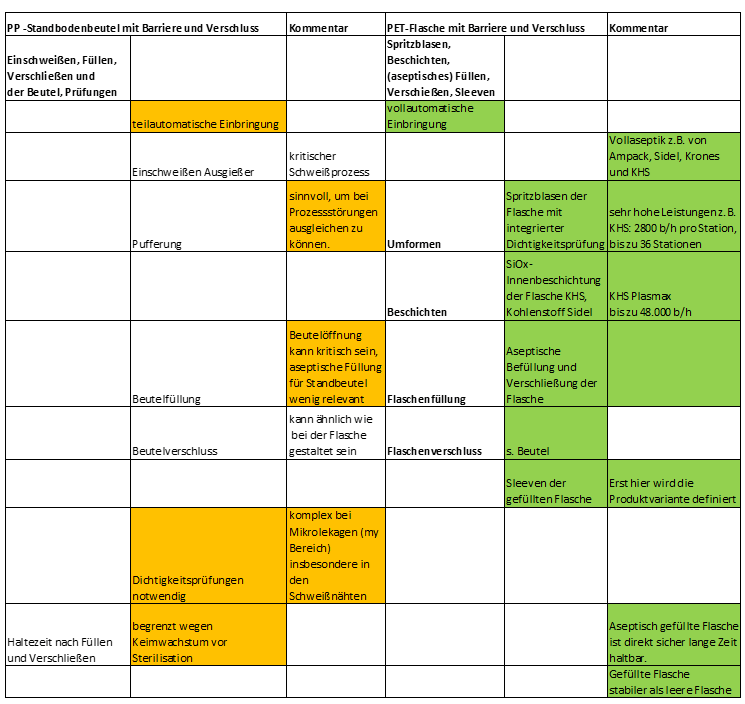

Table for Chapter 3: Finishing, filling and sealing processes

Sources:

/21/ https://www.toppan.com/en/living-industry/packaging/products/barrier_film/

/22/ https://www.khs.com/produkte/maschinen-anlagen/detail/khs-innopet-blomax-serie-v, homepage 2026

/23/ BMBF Final Report 13 N 8906, 2008

Improved residual emptying of packaging through plasma-based interior coatings in the nanometer range

/24/ https://www.ampack-solutions.com/#losungen

/25/ https://competence.khs.com/technologie/mehr-drin

/26/ https://www.krones.com/en/products/machines/the-labeller-for-sleeves.php

/27/ https://www.krones.com/de/unternehmen/presse/bereit-fuer-den-industriellen-einsatz.php

Leave a Reply