PP stand-up pouches vs. PET bottles for high-quality and sensitive fillings – a report by Dr. Bernd Knierbein

As by January 2026, part 2 from 5, part 1 here:

2. Manufacturing processes for packaging

The manufacturing processes for both types of packaging differ significantly in terms of complexity and efficiency due to the different production principles. Continuous processes such as extrusion, printing and laminating are used for the films in the bags, while almost exclusively discontinuous processes such as injection moulding and stretch blow moulding are used for the bottles.

In general, it can be said that each individual continuous process incurs higher start-up losses than discontinuous processes such as injection moulding and stretch blow moulding.

2.1 Primary moulding process

Primary moulding refers to the production of solid geometric bodies, such as moulded parts from formless materials such as granulates. These processes are the most important type of shaping for thermoplastics. In many cases, such as injection moulding, no post-processing is required.

2.1.1 Continuous extrusion processes

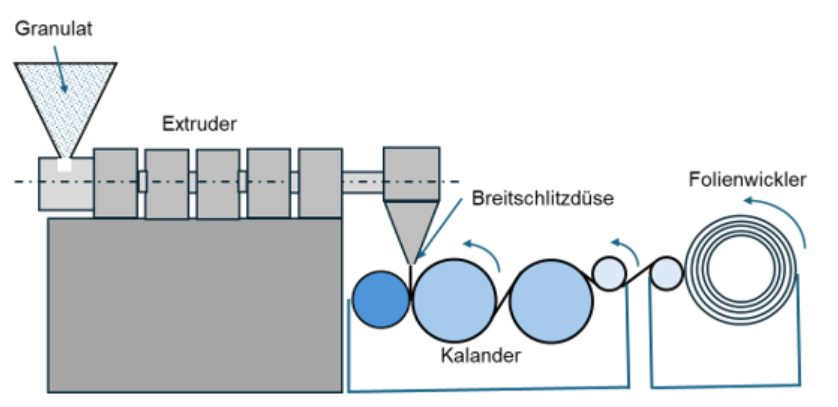

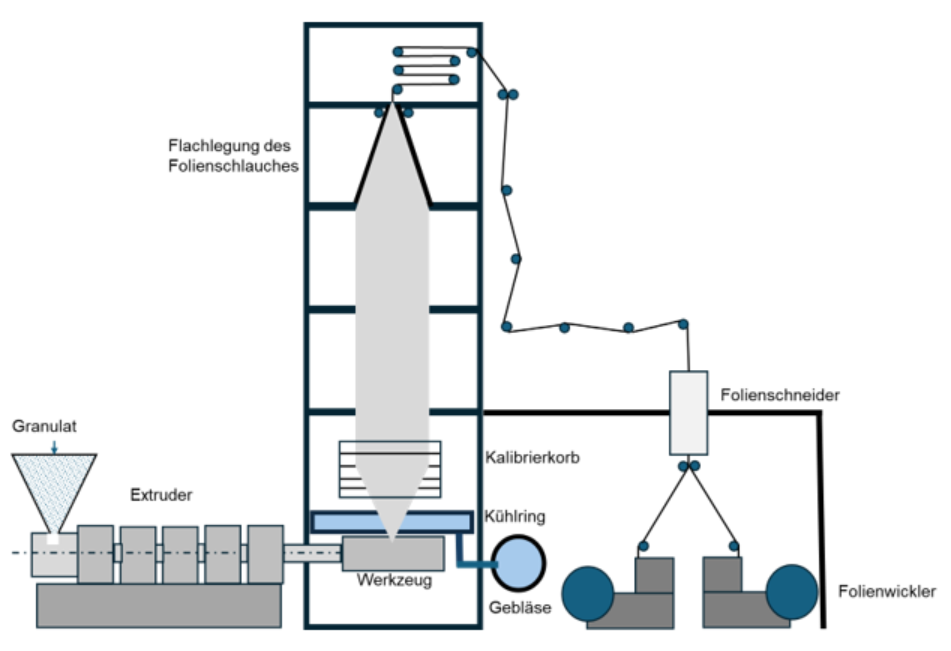

The film components of the bag are generally manufactured using continuous extrusion processes and are also further processed using continuous processes for coating, printing and laminating. The extrusion itself is carried out using both flat film (see schematic diagram in figure 2.1) and blown film processes (see schematic diagram in figure 2.2) /2, 12/. Examples of actual flat film systems can be found in /13/.

Figure 2.1. Schematic diagram of flat film systems

Pure clean production waste such as edge trimmings can be reused directly in film production after collection and shredding.

Figure 2.2. Schematic diagram of blown film lines

Real manufacturing facilities can be found, for example, under /2/.

2.1.2 Discontinuous process for the bag for the spout

The spout parts are manufactured discontinuously using conventional injection moulding /14,15/ and later added to the bag for welding.

2.1.3 Discontinuous processes for the bottle preform

The preform is produced discontinuously in injection moulding with the highest possible number of cavities in moulds (n > 100 possible) separately from the subsequent stretch blow moulding processes in a two-stage injection stretch blow moulding process. /14,16/.

The cooled preforms are transported in cartons or octabins to the injection blow moulding machine, where they are filled into hoppers. The preforms can then be blown up in the stretch blow moulding machine upstream of the filling machine.

2.2 Conversions (further processing)

2.2.1. Stand-up Pouches

2.2.1.1. SiOx coating of OPP

The transparent barrier coatings are usually applied in batches under high vacuum, which requires a high level of plant and process expenditure. The current coating widths in such plants are well over 2 m. The necessary equipment is now available at several manufacturing sites in Europe, America and Asia /3/.

The roll-to-roll process was developed to avoid the disadvantages of batch operation on the coater /17/.

- Unwinding the film at ambient pressure

- Introduction into the vacuum chamber via a lock system

- Application of the SiOx layer under plasma in the vacuum chamber

- Transfer of the film through an airlock system to ambient pressure and winding

2.2.1.2 Printings

There are two common methods for printing on the reverse side of OPP film:

- Flexographic printing

- Gravure printing (/18/ see figure 2.3.)

Figure 2.3. Gravure printing press

As an alternative to reverse printing (see figure 1.1), frontal flexographic printing on the outside of the composite is also possible, but this is less suitable for higher loads such as pasteurisation and sterilisation.

Digital printing is also possible for smaller print runs without sterilisation loads.

2.2.1.3 Laminations

In the case of the triplex composite, two laminations are required. The following steps are recommended for reverse printing:

- Pre-composite: oPP+SiOx/cPP

- Final composite: oPP + reverse printing + pre-composite

Fundamental losses due to start-up and cutting processes:

Cutting processes are necessary for all film processing steps in order to trim the edges of the further processing widths for laminating, printing and bag machines. Due to the lack of purity of type, the cutting waste is less recyclable than in the above-mentioned pure extrusion.

2.2.1.4 Welding the bag contour and, if necessary, welding in the spout

At the end of the conversion process, the bag contour is welded. In many cases, the upper and lower webs and the bottom strip are fed into the bag machine separately. A different film structure can also be selected for the bottom strip, e.g. for better drop resistance or other desired properties.

The welding process used is usually heating element welding with heating and cooling jaws. Typical cycle times are around 1 second, which means that with two-lane production, output is around 7,000 bags per hour. Smaller bags can also be produced with significantly higher lane numbers and correspondingly larger quantities per unit of time.

Another welding method is ultrasound, for which initial commercial applications already exist for both bag and spout welding /19, 20/.

A spout can be inserted during the production of empty bags, but this leads to significantly more complex logistics for the empty bags, as they can no longer be packed flat and therefore have to be threaded onto rails.

2.2.1.5 Additional opening and closing aids

For larger bag openings, e.g. for chunky fillings, laser perforations in the top of the bag are suitable as an opening aid or, if resealing is desired, a heat-sealed zip. With these types of closure, filling is only possible through the upper open end of the bag, which is then sealed by heat sealing.

2.3 Sleeve for PET bottle

The sleeve film used to coat the PET bottle is the only component that is manufactured continuously for the bottle. The printing processes mentioned in 2.2.1.2 can be used for this purpose.

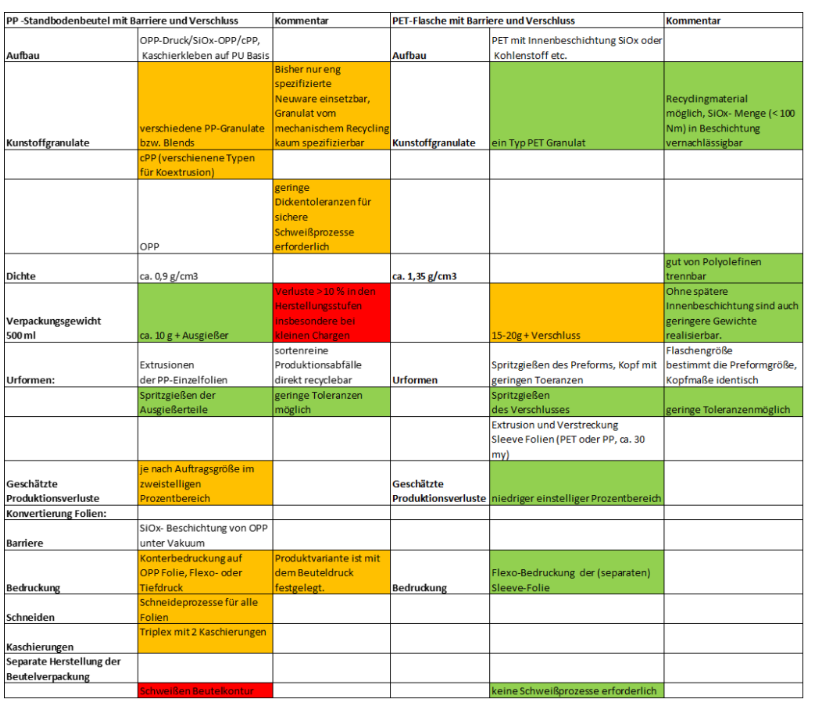

Table for Chapter 2

The tables are colour-coded in the comparative assessment:

- Green: Uncomplicated and easy to manufacture in large quantities

- Yellow: Not a fundamental problem, but time-consuming

- Red: Critical processes involving risks and/or high costs

Sources:

/12/ Christian Hopmann, Walter Michaeli: Introduction to Plastics Processing, 8th updated edition, 2017, Chapter 6.1.2.3. Examples of flat film and blown film extrusion lines.

/13/ Benjamin Pott, Evaluating the Potential of Cast Films and MDO Technology, Inno-Meeting: Minimum Packaging Flexpack – Trends and Technologies 2025

/14/ Christian Hopmann, Walter Michaeli: Introduction to Plastics Processing, 8th updated edition, 2017, Chapter 6.3. Injection Moulding

/15/ Lea Middendorf: Sustainability and technology combined – Spouts for stand-up pouches, 8th European Stand-Up Pouch Conference, 6 and 7 November 2024

/16/ Christian Hopmann, Walter Michaeli: Introduction to Plastics Processing, 8th updated edition, 2017, Chapter 6.2.2. Stretch blow moulding

/17/ https://www.kunststoffe.de/a/news/recyclingfaehige-barrieresysteme-fuer-na-2795910, July 2022

/18/https://www.bobst.com/chde/produkte/tiefdruck/tiefdruckmaschinen/

/19/ Stefano Di Maiolo: High-performance mono-material pouches with ultrasonic sealing, 8th European Stand-up Pouch Conference, 6 and 7 November 2024

/20/ Michael Baumann SUPs & PPWR – Valuetainable with ultrasonic sealing 8th European Stand-Up Pouch Conference, 6 and 7 November 2024

Leave a Reply