PP stand-up pouches vs. PET bottles for high-quality and sensitive fillings – a report by Dr. Bernd Knierbein

As of January 2026 Part 1 of 5

Introduction

Stand-up pouches and PET bottles dominate the European packaging market like no other plastic solution. In 2023 alone, around 59 billion stand-up pouches and approximately 135 billion PET bottles were produced /1/. These figures impressively underscore the central role both types of packaging play in everyday life—from food to sensitive premium products.

The following articles compare both packaging concepts specifically for particularly demanding applications—along the entire process chain from production and filling to use:

- The sterilizable PP stand-up pouch with barrier properties, opening and optional closure systems

- The PET bottle with barrier, closure, and aseptic filling technology

The aim is to clearly identify the respective strengths and limitations of both solutions in the context of high-quality and sensitive filling materials.

Triplex film structure for stand-up pouches

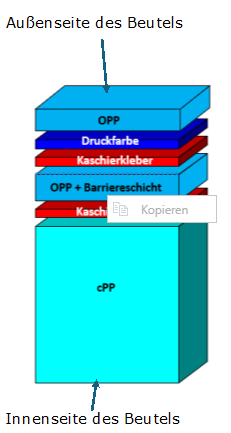

The PP stand-up pouch is constructed from a multi-layer composite (Figure 1.1):

The outer side of the film composite /2/ consists of a counter-printed OPP film laminated to a SiOx-coated OPP film. The SiOx coating thicknesses are very low, generally less than 100 nm, and are therefore hardly relevant for subsequent recycling /3/.

New options exist in the use of laminating adhesives with good barrier functions /4/, which eliminate the need for coating.

On the sealing side, a thicker PP film, which is often coextruded from several layers, is laminated onto the SiOx-coated OPP film. The laminating adhesives used are usually based on polyurethanes.

The empty weight of a 500 ml bag is approx. 10 g plus approx. 2 g in the case of the additional spout. The density of the PP types is in the range of 0.9 g/cm³.

The spouts and closures are mainly made of polyolefins, which must be weldable to the sealing layer of the bag in the shuttle area.

Figure 1.1: Composite film structure for PP stand-up pouches with ceramic barrier

Structure of the PET bottle

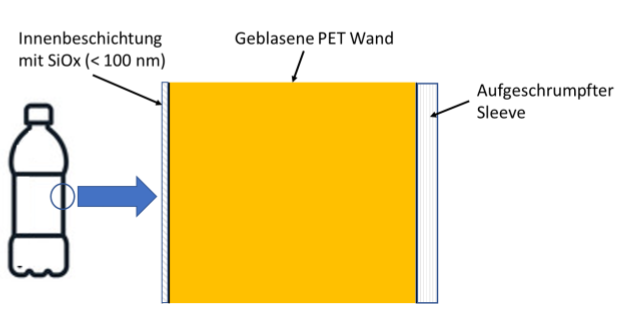

Compared to the composite film mentioned in 1.1, the wall structure of the PET bottle /5,6/ is significantly simpler due to the uniform base material and can therefore be manufactured extremely economically in just a few steps /7/.

A great deal has also been done in recent years to reduce weight. For Interpack 2026, 500 ml PET bottles for water (without additional barrier) weighing only about 5 g have been announced /8/.

The inside of the bottle can be coated with SiOx /9/, e.g., using the Plasmax process from KHS, or with carbon using the Actis process from Sidel (Tetra Laval) /10,11/ (Figure 1.2.). Due to the vacuum process, these bottles require slightly higher rigidity and therefore higher bottle weights than those mentioned above.

The internal ceramic layers also create a functional barrier against migration, which is currently often a prerequisite for the use of PET recyclates in the food sector /11/.

The densities of PET types are in the higher range for plastics, at 1.3 g/cm³. Due to the high difference in density, polyolefins with lower densities of around 0.9 g/cm³ can be easily separated from PET mechanically during recycling.

Figure 1.2: Wall structure of a PET bottle with an inner coating, e.g., made of SiOx, and a shrunk sleeve

The printed tubular sleeves are shrunk onto the bottle after filling, if necessary, and are made of either PET or polyolefins.

Sources:

/2/ Susanne Zobel-Reusch: STAND-UP POUCHES -SUSTAINABLY WELL POSITIONED WITH PE & PP MONOFILMS – 8th European Stand-up Pouch Conference, 6 and 7 November 2024

/1/ Jörg D. Schönwald: Stand Up Pouches on the Way to the Future – 8th European Stand-up Pouch Conference, 6 and 7 November 2024

/3/ https://www.toppan.com/en/living-industry/packaging/products/barrier_film/

/4/ The future of MAXIVE a gas barrier adhesive for mono-material packaging – 22. Inno-Meeting: Minimum packaging Flexpack – Trends and Technologies 2025

/5/ https://www.kunststoffe.de/a/grundlagenartikel/polyethylenterephthalat-pet-285552, edition 12/2025

/6/ Michael Thielen, Klaus Hartwig, Peter Gust: Blasformen von Kunststoff Hohlkörpern, Karl Hanser 2006, Chapter 3 stretch blow moulding

/7/ https://www.khs.com/produkte/maschinen-anlagen/detail/khs-innopet-blomax-serie-v

/8/https://www.interpack.de/de/Media_News/interpack_Magazin/GETR%C3%84NKEVERPACKUNGEN/Getr%C3%A4nkeverpackungen_News/The_lightest_Bottle_of the_World

/9/ https://competence.khs.com/technologie/erfolgsmodell Innopet Plasmax 12.6.2024

/10/ https://www.sidel.com/machines-repository/sidel-actis-coating/

/11/ https://www.sidel.com/de/about/media/press-release/actis-apr/